Previous Quizzes

Winner of the Quiz

Yeshwant Anandan

Kiewit

Incremental Launch Quiz Series

11 - 17 Dec 2025

Week 5 – Strengthening for Full Cantilever

Estimated Time: 4–5 min | PDH/CPD: 0.5 hr | Difficulty: Intermediate

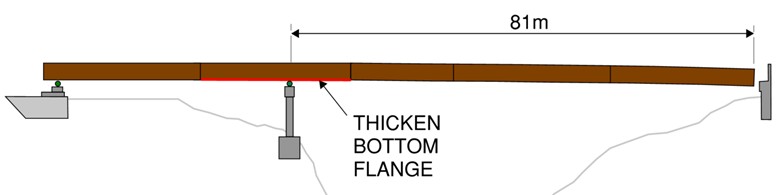

Background: The Sombrio bridge is a two-span composite steel plate girder bridge (40 m + 82 m) launched across a deep ravine in Port Renfrew, BC. Four plate girders were incrementally launched without a temporary pier or launch nose, using precast deck panels as tail counterweight, thickened pier-segment bottom flanges, and crane-assisted final lift. (Parameters simplified for conceptual learning. Allow +25% for cross-frames, connection & splice plates. Girders launched without formwork; ignore wind.)

Engineer's Mind: Quiz 4 showed current pier segment (65 mm bottom flange) cantilevers only 75 m—7 m short of 82 m span. Two options exist: provide 15–20 m launch nose (adds self-weight) or strengthen girders to cantilever to 81 m, with final 1 m crane-assisted for bearing placement. Given trade-offs, evaluate additional steel required by thickening pier segment bottom flange.

Question: Current section (65 mm bottom flange) allows 75 m cantilever. To reach 81 m, what bottom flange thickness is needed? Assume increase in thickness is proportional to flexural demand increase.

Given:

- Current: 75 m cantilever with 65 mm bottom flange

- Target: 81 m cantilever (8% longer)

- Capacity approximately proportional to bottom flange thickness

- 72 mm

- 75 mm

- 76 mm

- 80 mm

Explanation

Calculation:

- Moment demand: wL2 /2

- Moment ratio is equal to the ratio of the cantilever length squared: (81/75)² = 1.166 (17% more capacity needed)

- New bottom flange thickness = 65 × 1.166 = 75.8 mm ≈ 76 mm

A 17% thickness increase (65→76 mm, adding 11 mm) extends cantilever from 75 m to 81 m (6 m longer). This eliminates the ~$200k launch nose, adding only ~$35k-50k in permanent steel. The modest material addition (~0.23 m³ per girder, ~7 tonnes total across 4 girders) provides superior value: no schedule impact, no throw-away costs, enhanced safety margin for girder stability in the critical negative flexure zone above the pier. This demonstrates effective value engineering—small strategic strengthening eliminates expensive temporary works.